Both high-vacuum and low-vacuum systems are used to separate and filter dust and particulate matter, but there are differences between them. First, as their names suggest, they use different pressures. Second, they also utilize different fans.

I. Differences

1. Pressure Difference

High-vacuum vacuum systems generally operate in the high-pressure range of -20-120 kPa, resulting in faster airflow. Low-vacuum vacuum systems, on the other hand, operate in the low-pressure range of -5-10 kPa, resulting in slower airflow.

2. Fan Difference

High-vacuum vacuum systems use high-vacuum fans, producing high airflow. Low-vacuum vacuum systems use low-vacuum fans, producing moderate airflow.

2. High-Vacuum Vacuum System

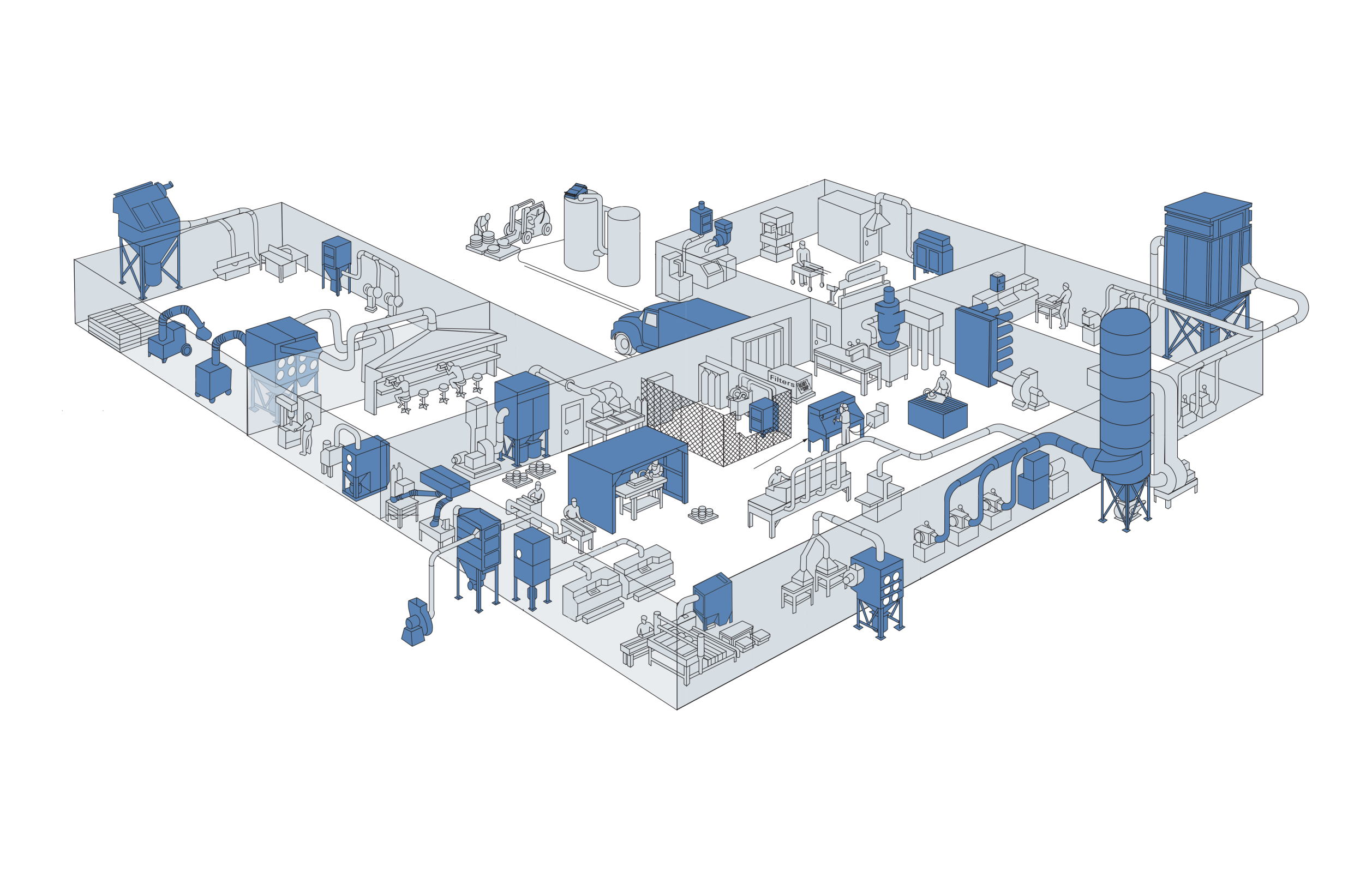

The high-vacuum vacuum system is suitable for precise dust capture in small areas. It can handle small-scale, source-based capture and cleaning, heavy dust particles and fine debris, and floor and equipment surface cleaning. Its unique feature is its ability to precisely capture and process dust before it spreads, effectively reducing secondary pollution. Its high air velocity facilitates centralized dust collection and significantly improves cleaning efficiency.

3. Features of the High-Vacuum Vacuum System

1. The fan generates a negative pressure exceeding 20 kPa, creating exceptional suction that efficiently and easily removes dust.

2. High-vacuum centralized dust collection prevents dust leakage, preventing secondary contamination.

3. The filter cartridge utilizes PTFE-coated filter media, achieving a filtration efficiency of up to 99.9%. Its built-in pulse backflush system maintains filter media clarity and durability.

4. It utilizes a PLC variable frequency control system, ensuring energy conservation and environmental protection, overload and overcurrent protection, and a built-in air supply system for high energy efficiency and stability.

4. Low-Vacuum Vacuum System

Low-Vacuum Vacuum Systems are suitable for handling dust-laden airflows with large dust-generating areas and high flow rates. They can handle large-scale dust generation, regional dust, and lightweight floating dust or smoke. Their advantage is their ability to effectively remove dust over a wide area.

5. Features of Low-Vacuum Vacuum Systems

1. The fan generates a low negative pressure of 5-10 kPa, enabling wide-area dust removal.

2. The filter cartridge utilizes PTFE-coated filter media, achieving a filtration efficiency of up to 99.9%. Its built-in pulse backflush system ensures long-term filter clarity and durability.

3. A spacious and airtight inspection door facilitates filter bag replacement and maintenance.

4. Equipped with overcurrent, overload, and leakage protection devices for enhanced safety, the system is also equipped with a silencer for quieter operation.

High-Vacuum Vacuum Systems are used in high-purity industries such as food, pharmaceuticals, semiconductors, and optoelectronics. Low-Vacuum Vacuum Systems are used for dust collection and treatment in industries such as cement and metallurgy. Therefore, different dust collection systems have different applications in different working conditions. Choosing appropriate equipment can improve the efficiency and quality of dust treatment, which has positive significance for reducing dust pollution and protecting the environment.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States