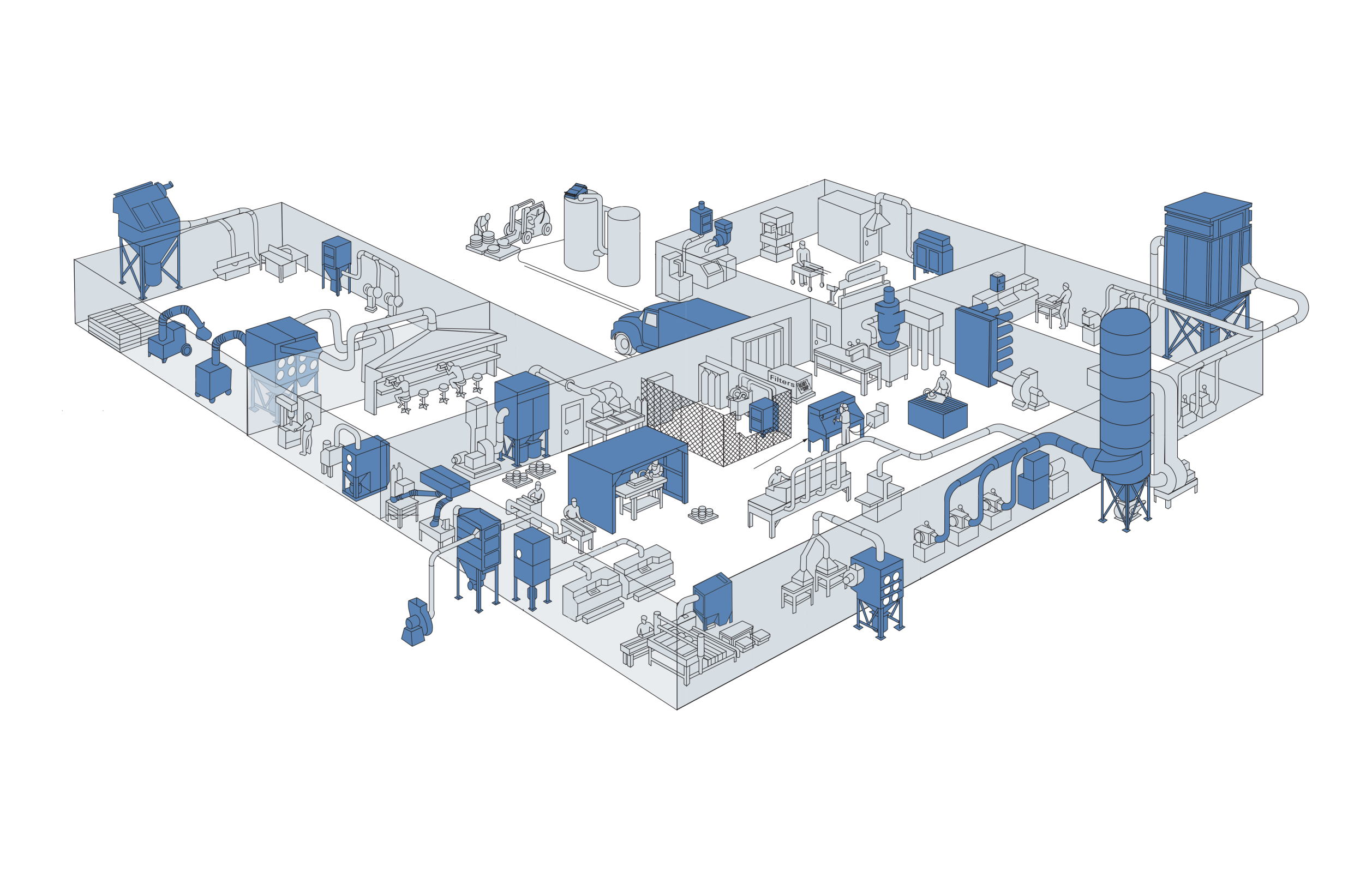

The SIB series bag filter dust collector is a heavy-duty dust collection system designed by Alfred for challenging processes and hazardous dust collection applications. This article briefly explains how this equipment works.

Dust-laden air enters the bag filter. As the airflow passes through the bags, the dust is trapped by the bags and adsorbed on their outer surfaces. The filtered, clean air then passes through the bags, enters the upper chamber, and is discharged through the fan.

As the dust collector continues to filter, dust accumulates on the bag surfaces, increasing the resistance of the dust collector. Therefore, regular dust removal, known as cleaning, is necessary. The dust collector uses compressed air pulse jet cleaning. The cleaning mechanism consists of an air bag, a jet pipe, and an electromagnetic pulse control valve.

A jet pipe is installed at the top of each bag outlet in the filter chamber. A jet port is located on the underside of the jet pipe, facing the center of the bag. Each jet pipe is equipped with a pulse valve and connected to the compressed air bag. The dust collector's cleaning function is implemented through differential pressure (constant resistance), timing, or manual control:

As filtration progresses, when dust accumulation on the bag surface reaches a certain level, the dust collector's resistance rises to a set value (generally 900 Pa). At this point, the dust collector's PLC, receiving a signal from the differential pressure gauge, initiates the cleaning process. The electromagnetic pulse valves open sequentially to inject compressed air. Compressed air flows through each pulse valve in a very short time sequence through the nozzles on the injection pipe, inducing several times the amount of air injected into the bag. This creates an air wave, causing the bag to expand and vibrate rapidly from the bag opening to the bottom. This causes the bag to vibrate completely and creates a backwash airflow from the inside out, creating a strong reverse cleaning effect, shaking off dust from the bag and achieving the desired cleaning effect.

The dust collector's cleaning function can also be implemented using a timing device built into the control system. Timing control and constant resistance control can coexist, with the cleaning process initiated by the control method that first meets the conditions. During maintenance, the cleaning function can also be manually controlled.

Each time the dust collector is cleaned, only one valve actuates, with an actuation time of 0.06 to 0.1 seconds. The interval between valves (injection interval) is adjustable from 0 to 120 seconds. The air volume (compressed air consumption) per valve cycle is 0.15 to 0.3 m³, the compressed air pressure is 0.4 to 0.6 MPa, and the compressed air quality is water- and oil-free.

The electromagnetic pulse valve and air bag are installed outside the clean air room and are protected from rain and frost. Except for bag inspection and replacement, which must be performed within the clean air room, all other dust collector maintenance and repair work is performed outside the dust collector operating area.

The dust collector is equipped with differential pressure detection and alarm functions.

The dust collector control (including cleaning control) is automated using a pulse controller. The entire dust collection system is automated and unattended, with the ability to provide feedback to the broader factory system and accept remote control.

This dust collector is a new type of high-efficiency dust removal and purification equipment with the characteristics of good cleaning effect, high purification efficiency, large gas processing volume, long bag life, easy maintenance, small workload, and reliable operation. It has been widely used in metallurgy, chemical industry, cement, casting, grain processing and other departments.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States