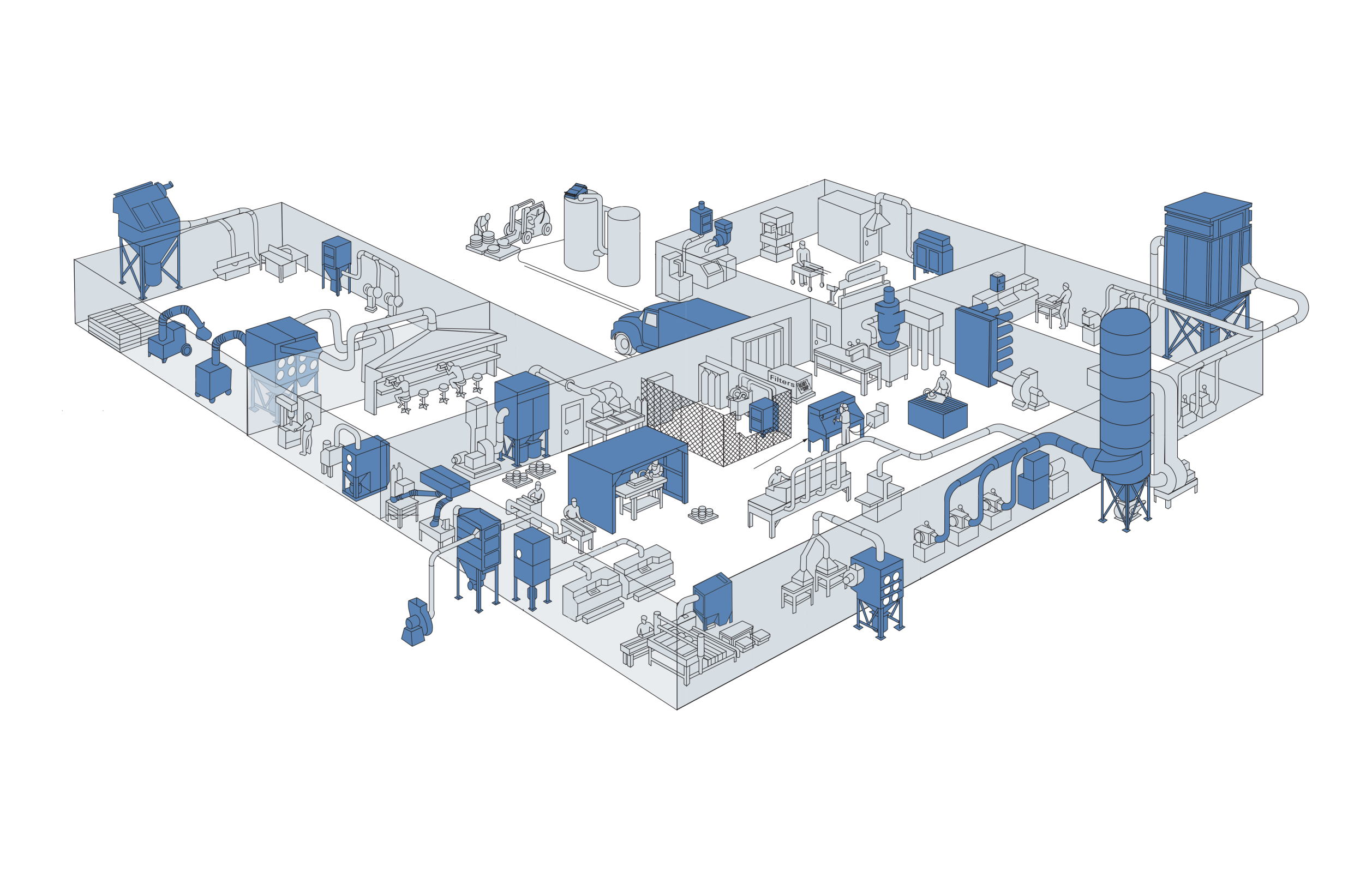

Alfred focuses on product development, understanding the critical importance of ensuring that the product is suitable for the application. Therefore, Alfred maintains a broad product portfolio, ensuring the appropriate product is selected for specific application requirements.

For every process and contaminant, a variety of technologies are available for effective capture. Careful selection of specific equipment and accessories will ensure years of system performance and operation.

Electrostatic precipitators are ideal for capturing submicron-level pollutants. Typical pollutants include welding fumes, oil mist, smoke, and other hydrocarbons generated by high temperatures. Typical applications include welding, wet machining, electrical discharge machining (EDM), and plastics processing fumes.

Media filtration units are ideal for capturing low-concentration dust and mist. Typical pollutants include welding fumes, oil mist, sanding dust and particulates, and dry powders. Typical applications include welding, wet or dry machining, and hand sanding.

Dust collection equipment is suitable for a wide range of pollutants. Cartridge filters are designed to capture welding and cutting fumes, dry powders, and dry machining dusts. Typical applications include welding and cutting, mixing and blending, material handling, and dry machining. Cyclone dust collectors are designed to capture dry dust larger than 10 microns. With the addition of a secondary filter, these systems can collect particles smaller than 10 microns. Typical pollutants include woodworking dust, dry powders, metal grinding dust, and plastic dust. Typical applications include woodworking, bulk powders, dry grinding, grain handling and dry plastics processing. Oil mist collectors are designed to capture oil and coolant mists, typically in wet machining operations.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States