The fume control in welding workshops has always been a technical problem. According to different welding processes, the use of appropriate ventilation systems and filtration methods can effectively solve the pollution problem of welding fume.

The control of welding fume is a comprehensive problem, and its difficulties are manifested in the following aspects:

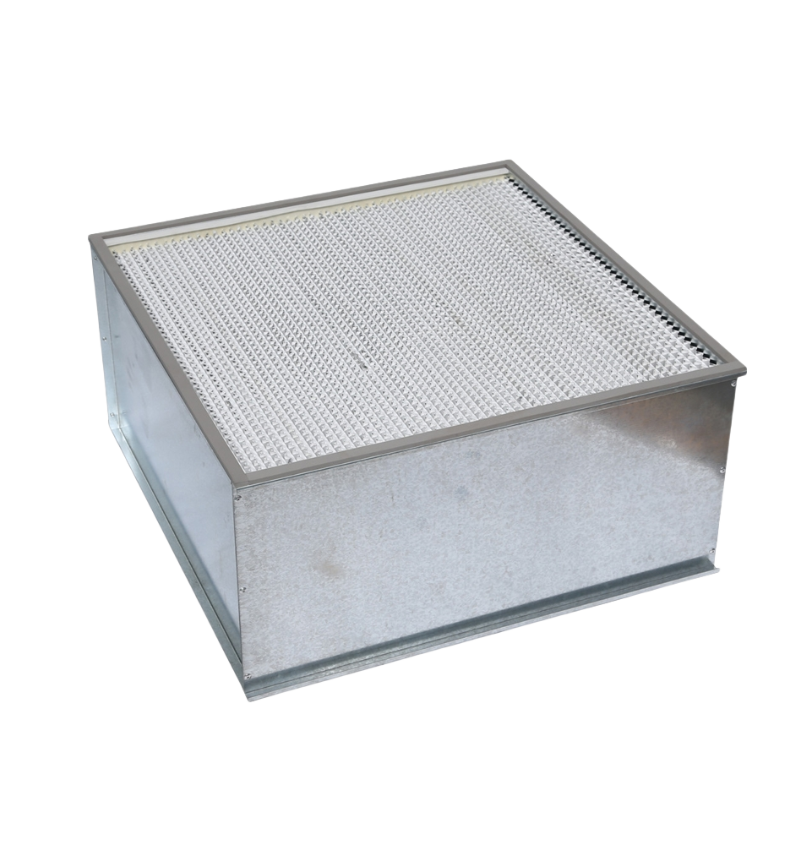

1. The particle size of welding fume is small, ranging from 0.01 to 10 μm, making it difficult to filter and purify;

2. The variability of welding stations, the large number of welding stations, and the large welding workpieces make it difficult to capture welding fumes;

3. There is a maximum concentration zone of smoke in the welding workshop, and it is difficult to remove dust using common ventilation technology;

4. Welding fume containing oil smoke is difficult to purify;

5. Auxiliary equipment takes up a lot of space and various pipelines are spread throughout the workshop.

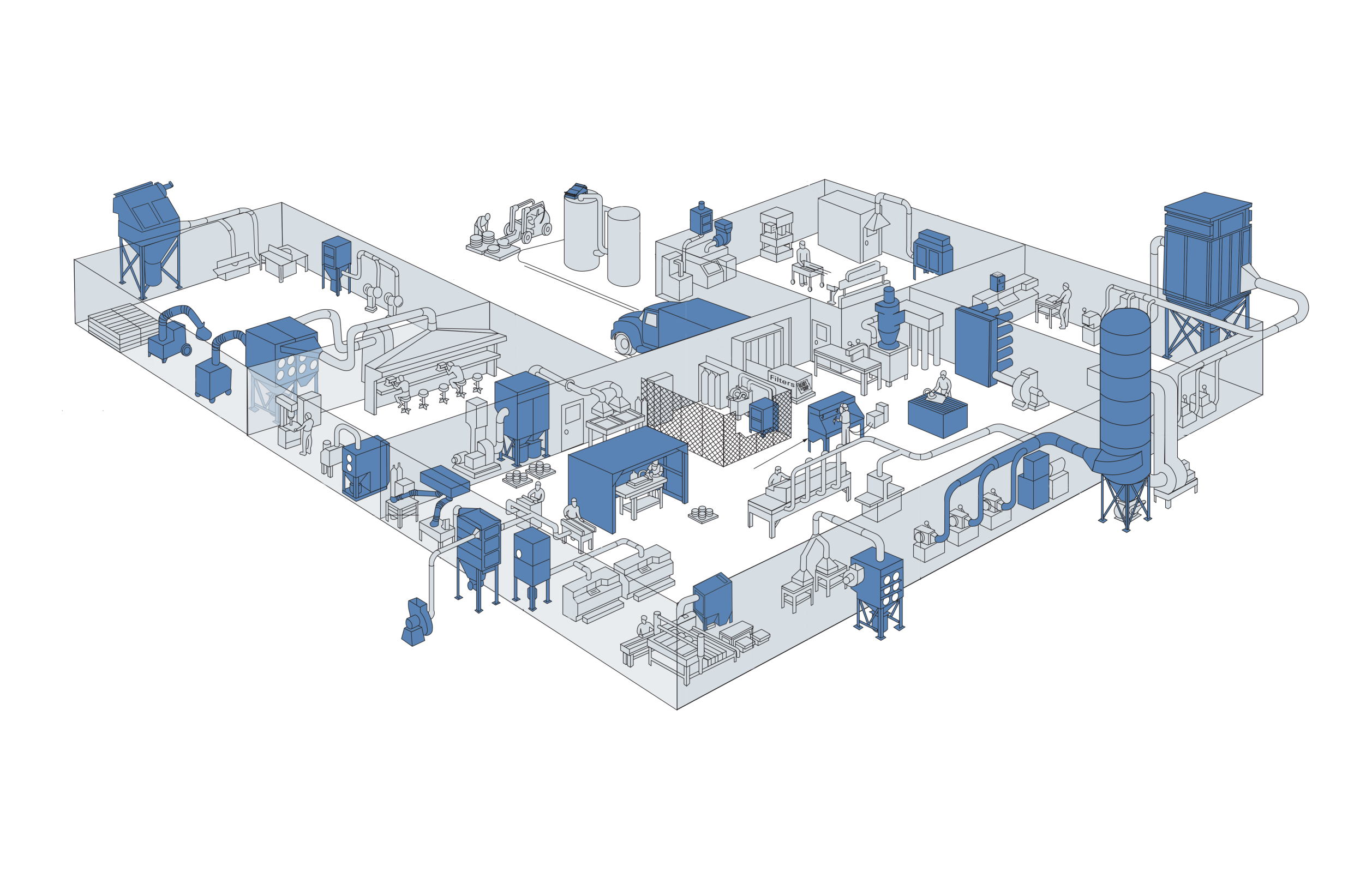

Alfred provides comprehensive solutions for different working conditions such as welding production lines, welding rooms, welding stations, and large-space welding. Its rich product portfolio ensures that users can choose the right products according to their application needs.

◆ Industrial plants with large welding fumes, large workpieces, many welding points, and complex welding processes

◆ Not suitable for welding production lines with single-point or conventional centralized management

◆ There are welding process requirements, such as humidity and temperature requirements

◆ The workshop needs to control temperature and humidity, such as insulation and heating requirements in winter and air conditioning systems in summer

◆ Based on the number of workstations and on-site conditions, system calculations such as air volume and pressure are performed to determine the smoke and dust capture plan, pipeline layout, dust collector and fan.

◆ Relying on a complex piping system consisting of centralized main pipes and split sub-pipes, supplemented by high-power large-scale dust collector hosts, it has been the mainstream dust removal solution for large workshops in the past decade.

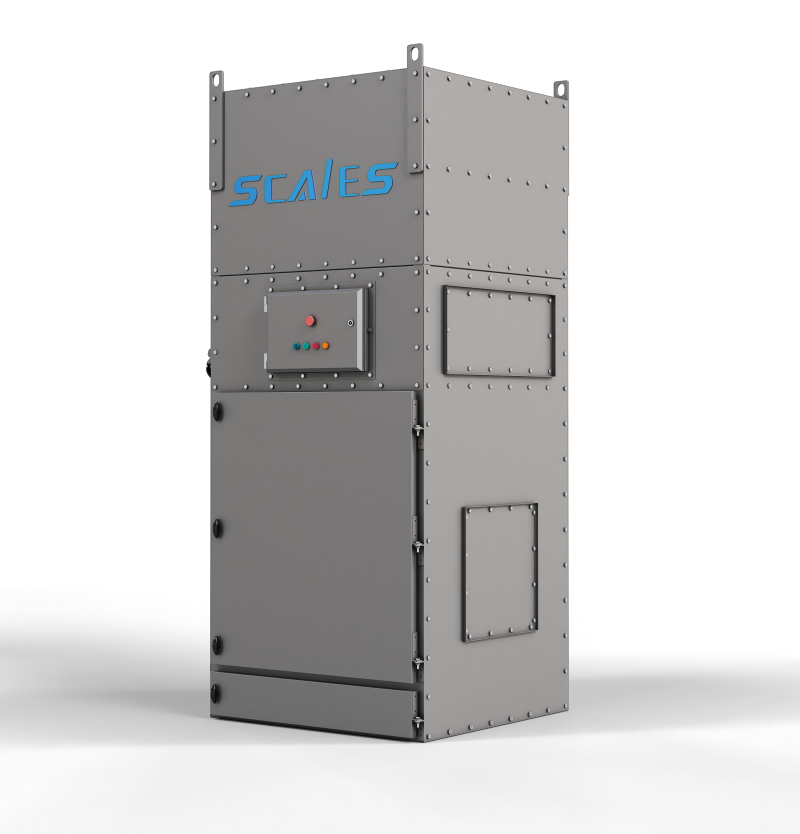

◆ Local welding fume control, strong flexibility

◆ Small size, no need for external pipes, can be flexibly arranged according to the on-site space

◆ Self-integrated design, complete functions and easy installation ◆ One-to-one or one-to-many, mostly used for welding robot welding fume control

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States