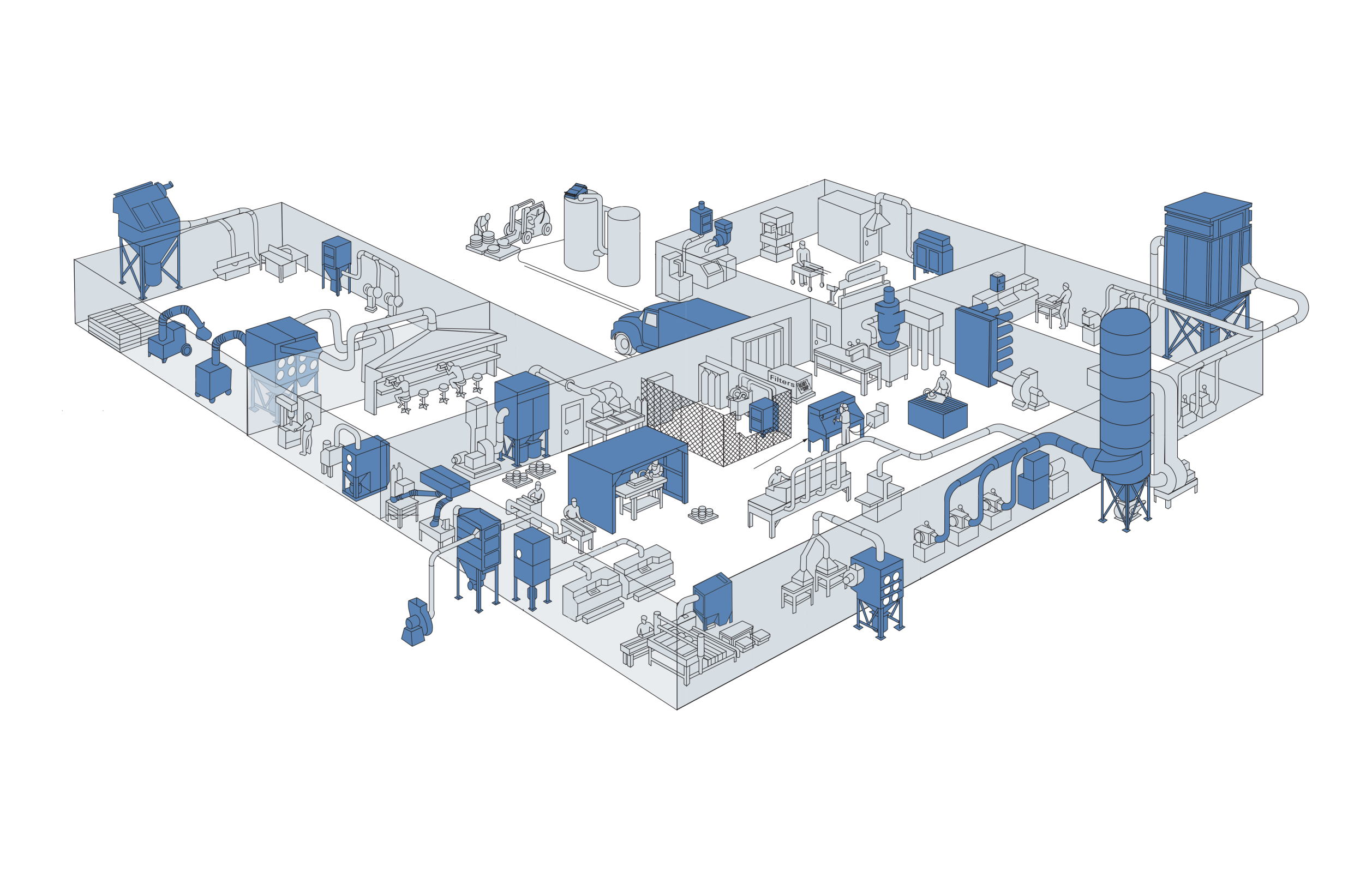

When combustible materials, ignition sources, and oxygen collide in a confined space, an explosion can occur. When factories need to collect and purify flammable and explosive dust to meet environmental regulations, careful explosion-proof safety design is essential from the outset of dust removal system planning.

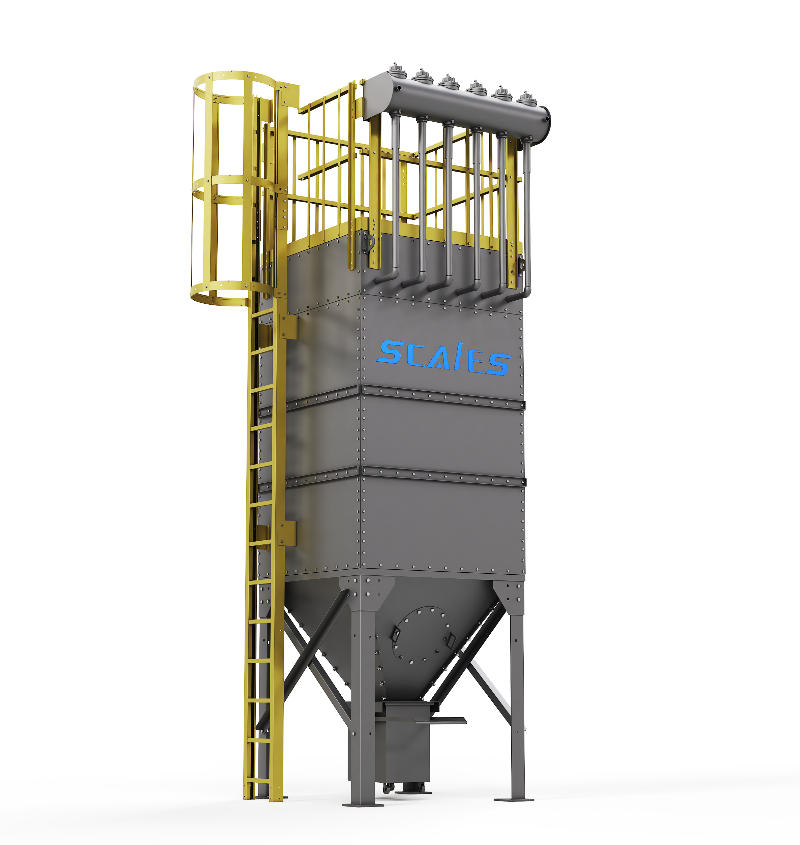

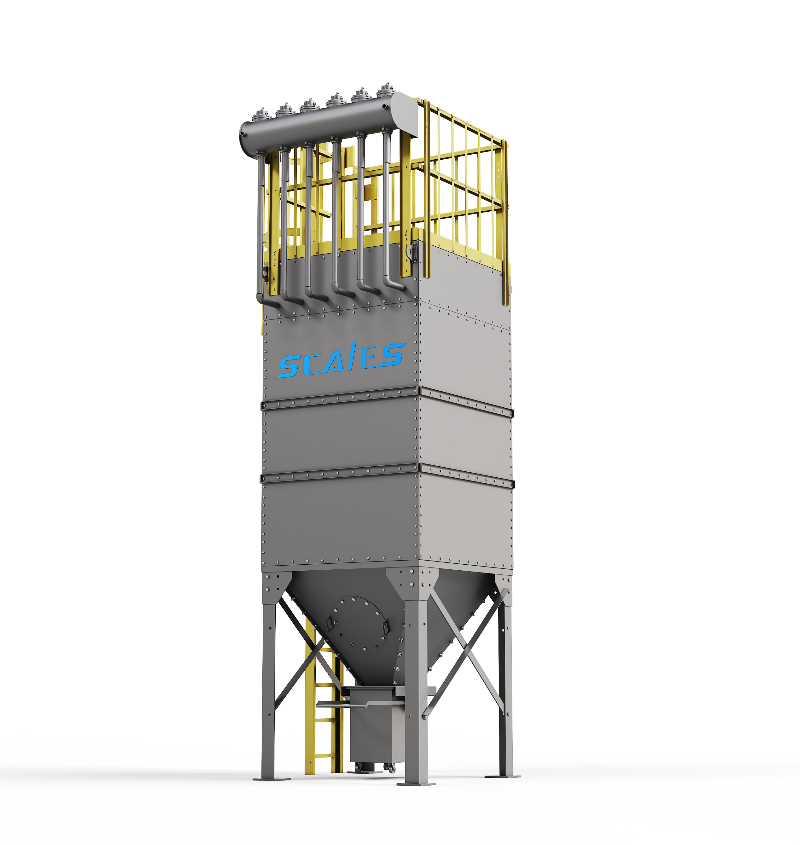

Production sites must be kept in a safe and protected state at all times. This ensures the safety of personnel and prompt resumption of production should an explosion risk arise. After all, every minute of production downtime represents lost profit. Experience suggests that systematic explosion safety measures can be implemented through the installation of explosion-proof windows, explosion-proof discs, explosion-proof solenoid valves, and explosion-proof dust collectors.

Cheap precautions can lead to expensive costs. We are happy to present you with explosion-proof dust removal solutions tailored to your actual situation.。

The dusts that are generally more prone to explosion accidents include aluminum powder, zinc powder, ferrosilicon powder, magnesium powder, iron powder, aluminum processing grinding powder, various plastic powders, intermediates of organic synthetic drugs, wheat flour, sugar, sawdust, dyes, bakelite ash, milk powder, tea powder, tobacco powder, coal dust, plant fiber dust, etc.

The reason these materials' dusts are prone to explosion and combustion is that they contain strong reducing agents such as H, C, N, and S. When these elements coexist with peroxides and explosive dust, they decompose, producing large amounts of gas from the oxidation reaction, or even small amounts of gas that release a large amount of combustion heat. For example, aluminum powder is at risk of explosion as long as it is in a carbon dioxide atmosphere.

Industrial production processes vary greatly depending on the industry and product. No two production processes are exactly the same. Explosive dust removal projects are different from ordinary dust removal projects, and we usually need to do the following additional work:

◆ 1. Understand the material safety data sheet of dust;

◆ 2. Understand the process that generates dust;

◆ 3. Understand the Kst value and Pmax value of explosive dust and define the explosion-proof level;

◆ 4. Classify the explosive areas of the dust removal system and configure mechanical and electrical equipment in each area that complies with ATEX standards based on the correct classification.

◆ 5. The technical department reviews the plan and a third party conducts a safety assessment.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States