Plasma cutting machines, flame cutting machines, and laser cutting machines generate a lot of smoke and dust during operation. The smoke and dust not only pollute the workshop environment and affect the health of workers, but also adhere to the surface of the equipment and affect the service life of precision components.

◆ According to the analysis of the dust properties generated during cutting, the particle diameter of the smoke is between 0.1-10um, and the smoke is free.

◆ When cutting alloy materials such as aluminum and magnesium, explosion-proof measures need to be considered.

◆ When the cutting workpiece contains oil, dust removal equipment, pretreatment device or powder adding device need to be added.

◆ When the power of the dust removal system is large, frequency conversion control can be used.

◆ Determine the filtration wind speed of the dust collector based on the smoke concentration, smoke particle diameter and oil content.

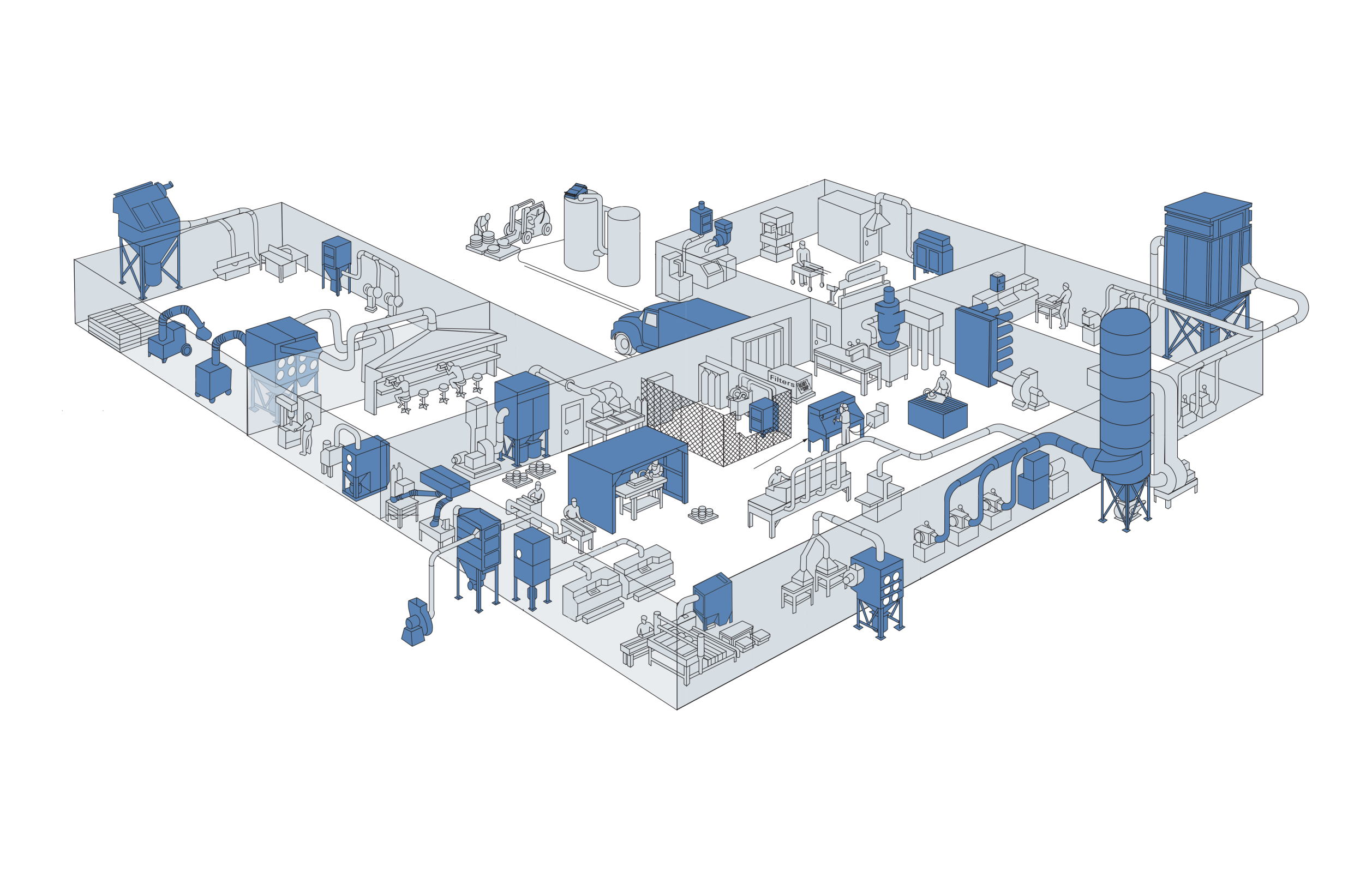

The method of controlling cutting dust depends on the method and process used. Alfred recommends the following grinding dust control solutions based on its own products:

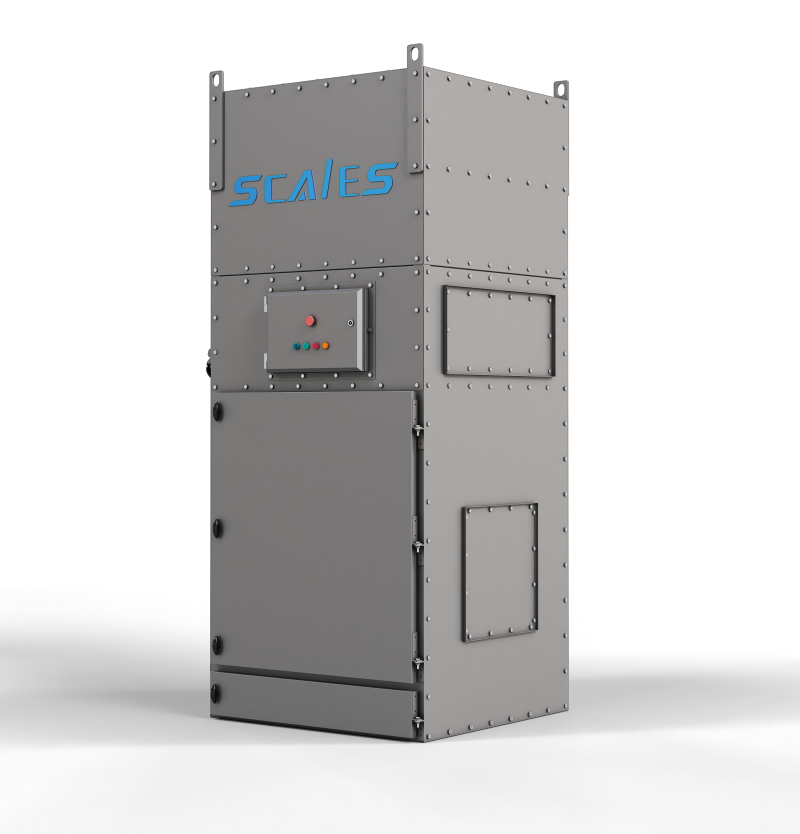

◆ Currently, most laser cutting equipment on the market is fully or semi-enclosed, with a pre-set flue to facilitate the installation of supporting equipment. For this type of laser cutting machine, a purifier can be connected to the cutting machine to collect smoke during operation. The smoke generated by cutting is then passed through the flue to a dust removal system, where it is purified and discharged to standard levels.

◆ During flame cutting and plasma cutting, a large amount of smoke is generated, and the dust in the smoke has the characteristics of settling. For such working conditions where a large amount of cutting smoke is generated, a single-sided suction trolley or a double-sided suction trolley can be used to collect and process the smoke.

◆ The specific method is to install a suction trolley on both sides or one side of the cutting table (depending on the table width). The suction trolley moves with the cutting head, generating suction to collect cutting dust. After collection, the dust passes through the flue to the dust removal host, which filters it and then discharges the clean air that meets the standards.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States