In machining workshops, the use of machining equipment often generates oil mist, dust, and exhaust gases with complex forms and compositions. These gaseous pollutants not only pollute the environment and pose a threat to the human body, but also adversely affect the precision and expensive machining equipment, shortening its service life.

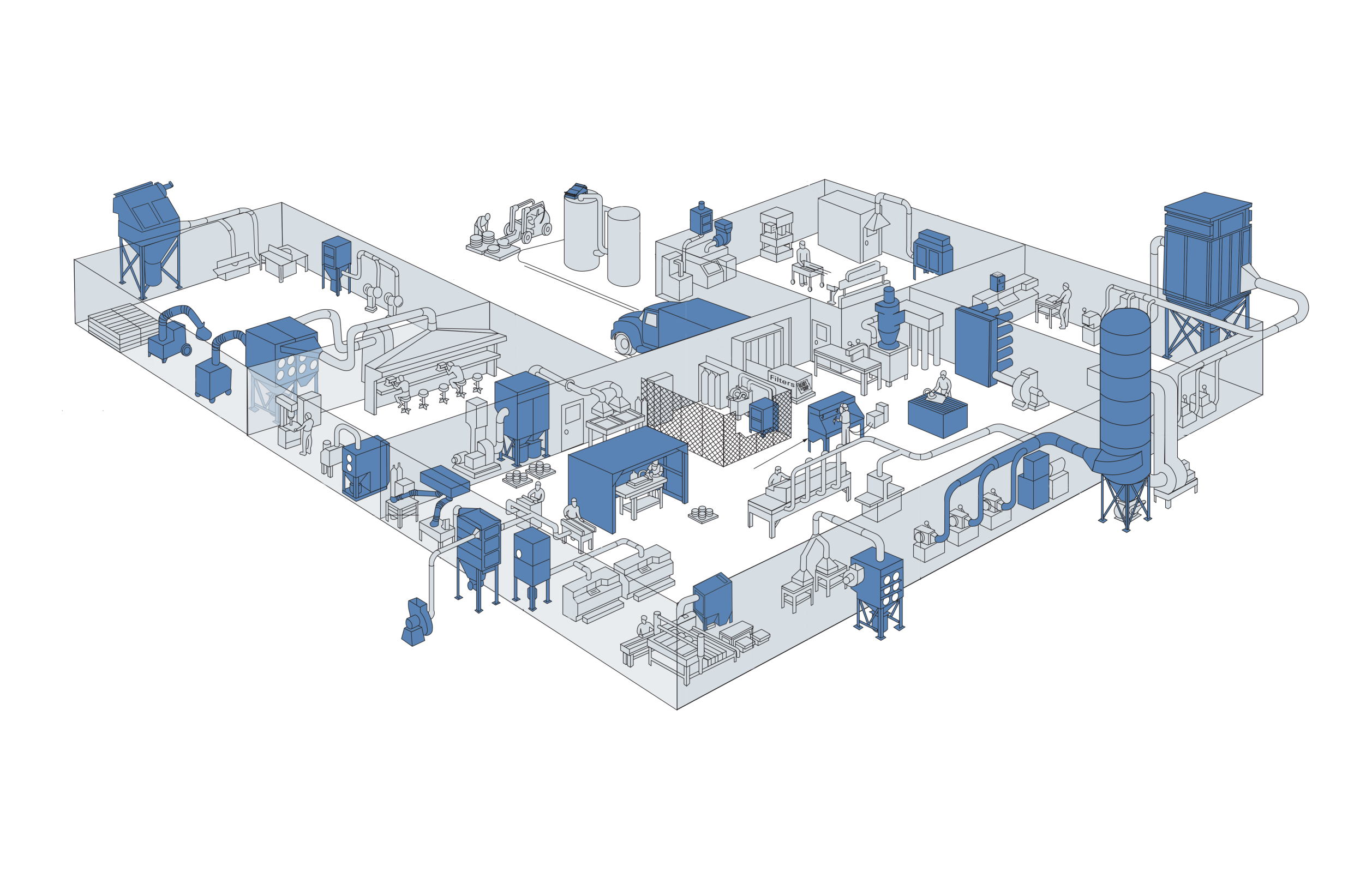

Alfred machine tool oil mist dust removal solutions are generally suitable for machine tool processing, cutting, stamping, die casting, cold heading, heat treatment, rolling, bearing processing, gear processing, precision parts processing, tool processing and other production and processing processes.

◆ Various filtration technologies such as electrostatic and mechanical types can meet the purification needs of different working conditions;

◆ From small to large purification equipment, meeting all air volume requirements;

◆ A variety of capture technologies, source capture, and reduced energy consumption;

◆ Personalized design to flexibly meet customers' special needs;

◆ Energy-saving and energy recovery design to continuously reduce operating costs;

◆ Turnkey project and one-stop service.

◆ Suitable for machining workshops with more processing equipment.

◆ Under the action of negative pressure, the oil mist enters the main pipe through the branch pipe on the machine, and then enters the oil mist treatment equipment for purification. The purified gas can be further deeply treated through the VOCs purification module and finally meet the emission standards.

◆ Suitable for oil mist treatment in complex workshop environments and compact spaces. Regionalized distributed treatment is implemented based on actual conditions such as machine placement and workshop height. Each distributed purification system can operate in a one-to-two or one-to-many configuration to treat oil mist.

◆ Each treatment system is professionally designed according to the workshop environment and is deeply integrated with the production process. There is no need to lay out a large-scale collection pipe network. After oil mist treatment, it can be directly discharged indoors to meet the standards.

◆ Each or every two machine tools is equipped with a dedicated oil mist collector, which can be placed on top of or next to the machining equipment and connected via a hose or pipe. This installation method is flexible and suitable for factories with relatively open spaces and high utilization rates.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States