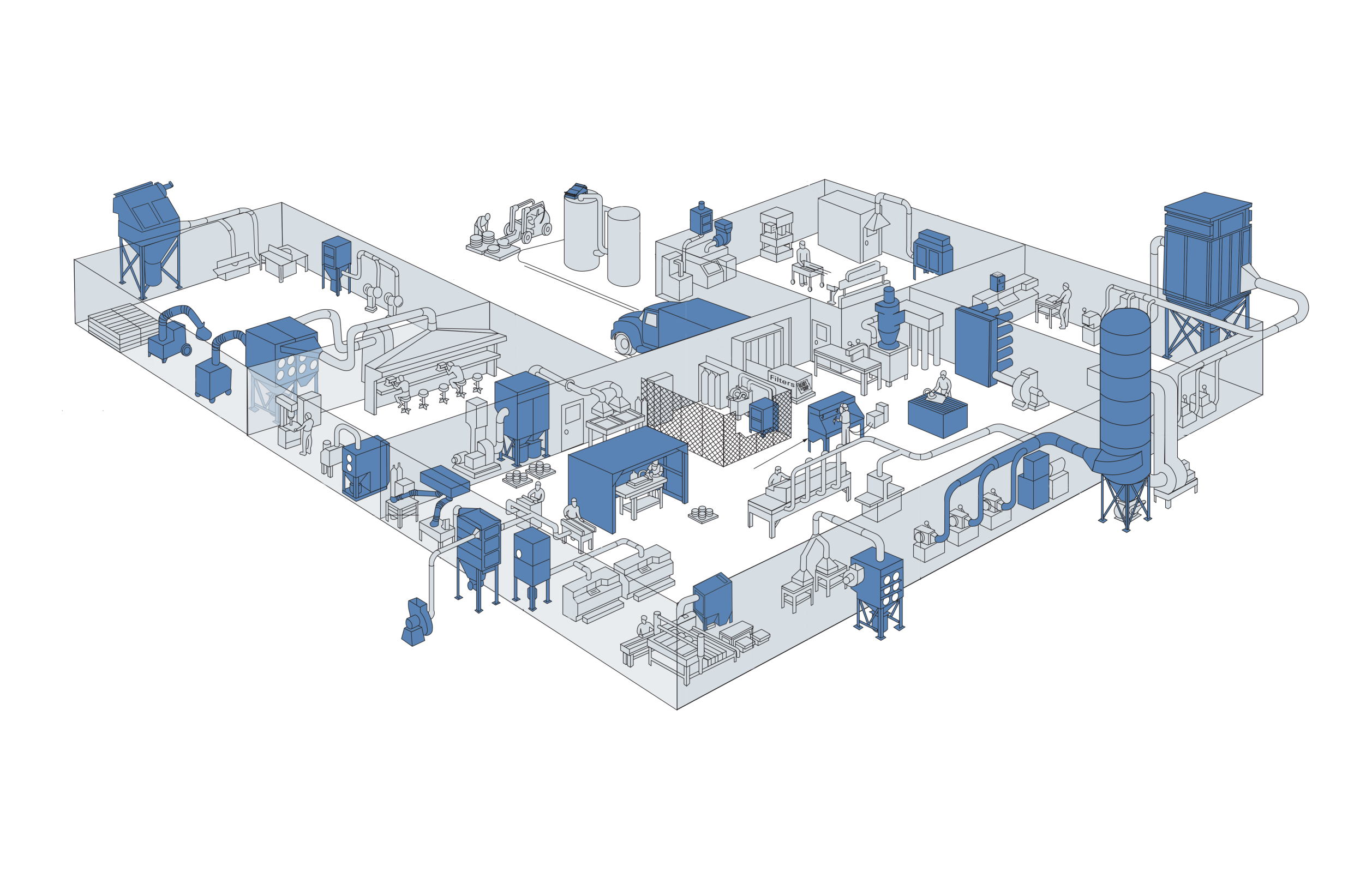

Foundry production is one of the industries that causes the most serious environmental pollution. The main sources of air pollutants are dust and smoke. The dust and smoke in the foundry mainly come from:

◆ Fumes and dust generated by smelting processes such as electric arc furnaces, medium frequency furnaces, and induction furnaces;

◆ Dust generated during the molding sand preparation process, such as sand mixing, sand handling, cleaning, molding, core making, mold closing, casting, mold opening, and sand falling out.

◆ Dust generated by processes such as casting cleaning, shot blasting, sand blasting, and grinding

The core of fume treatment solutions in foundries is the selection of suitable fume capture solutions and filter elements that can operate reliably and reliably in challenging environments such as high temperatures and heavy loads. Alfreds' extensive product portfolio provides a solid foundation for providing targeted solutions based on dust-generating processes.

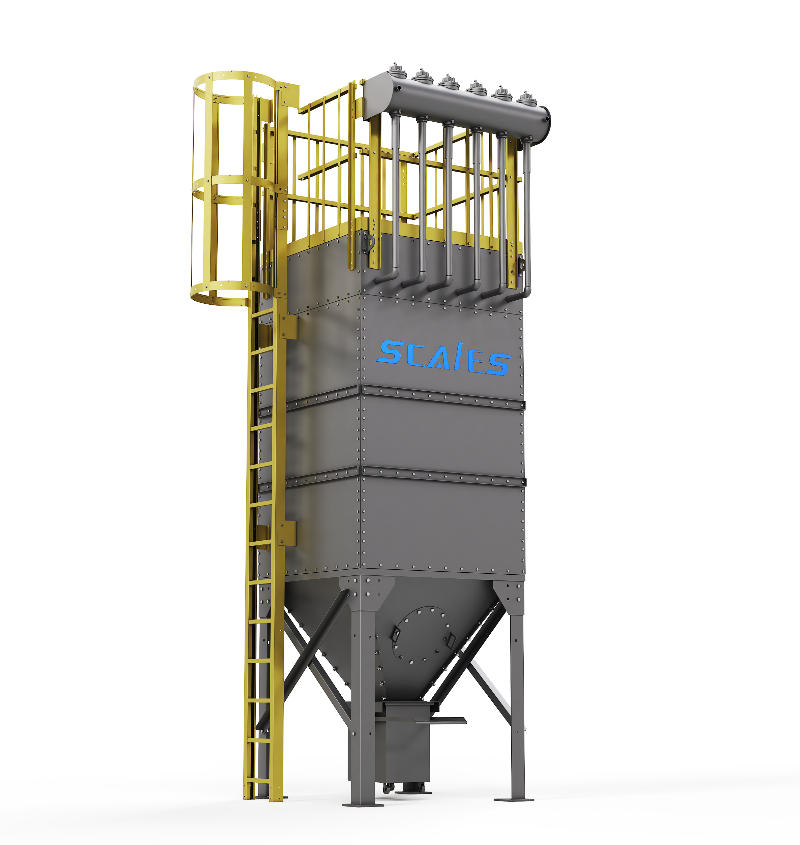

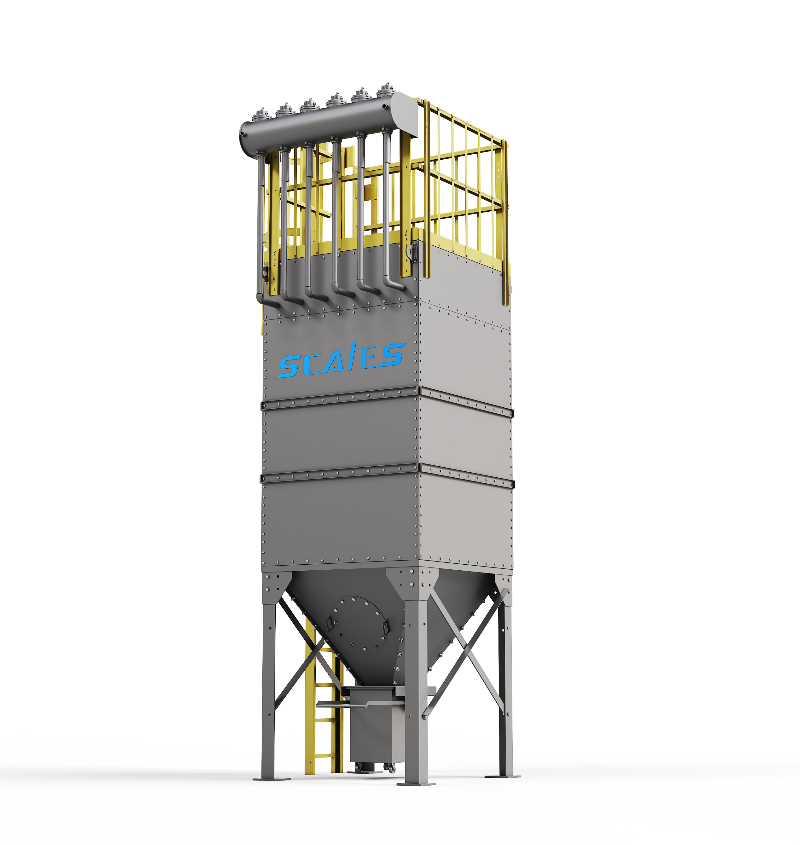

◆ Can handle high-concentration mixed airflow.

◆ Compared with conventional dust removal systems, it has a reasonable structure, small footprint, reduced total system resistance, low energy consumption and low investment.

◆ The efficient cleaning method and economical cleaning parameters fully reflect the high efficiency and energy-saving optimized design of the dust collector.

◆ Bags are specially selected according to the characteristics of the dust.

◆ There are no moving parts in the dust collector, making maintenance easy.

5030 Boardwalk Drive, Colorado Springs,United States

5030 Boardwalk Drive, Colorado Springs,United States